Big photo: China has prevented the export of significant rare earth metals and magnets, which are essential for industries ranging from motor vehicle manufacturing to aerospace and defense. The move, which sent shockwaves through global supply chains, began earlier this month when China imposed new export restrictions on these minerals.

The suspension comes in the form of Beijing, drafts a new regulatory structure to issue export licenses, a procedure that expects to restrict access to these important materials for specific companies, especially American military contractors. Industry leaders are afraid that delay in setting up the licensing system may lead to a shortage of rare earth components outside China.

American elements CEO Michael Silver told The New York Times that his company was informed that it would take at least 45 days since exports resume. “We estimated this trade war and increased its list in the last winter,” Silver said, their firm could complete the existing contracts in the interim.

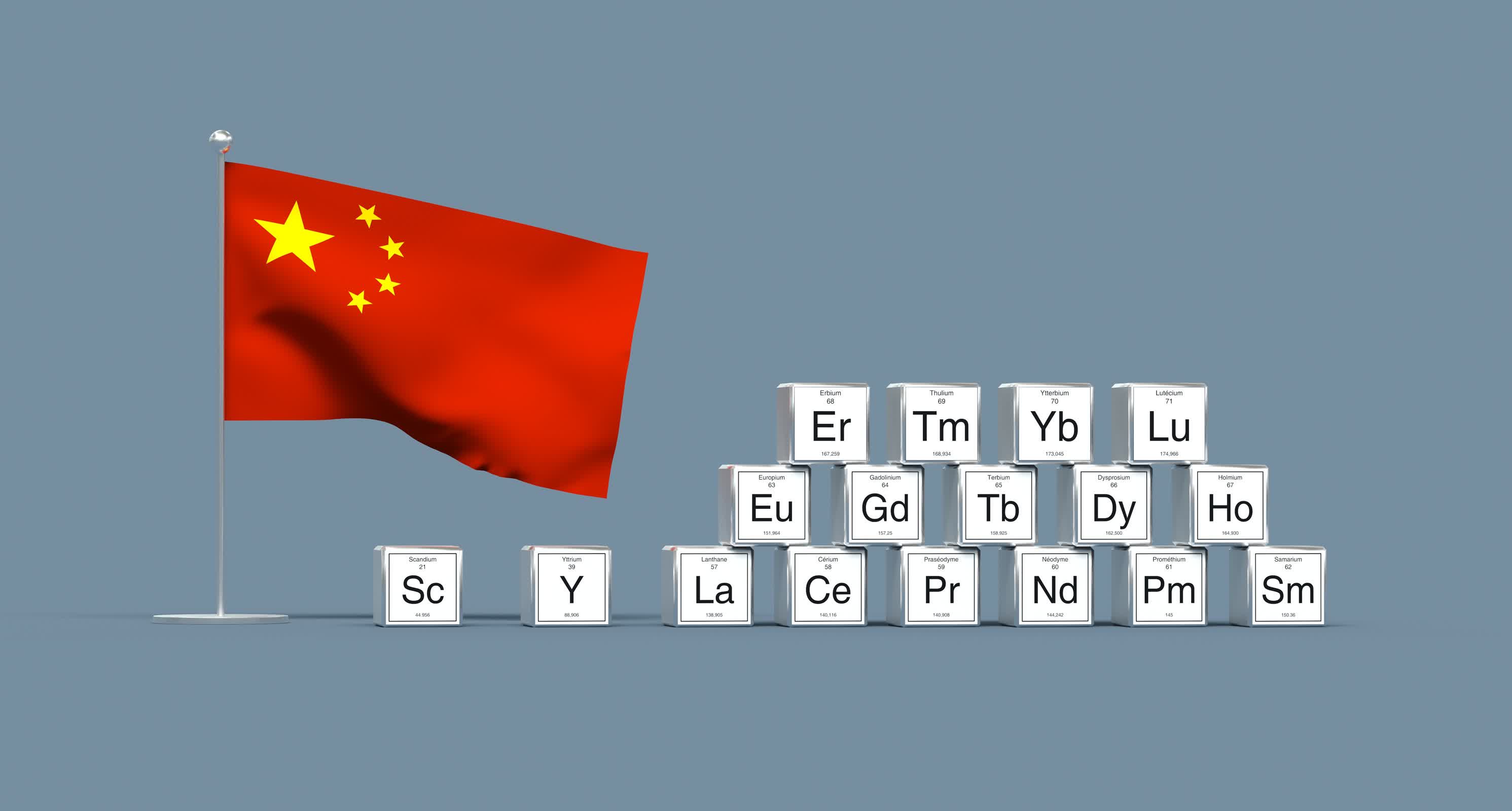

Rare Earth metal metals are indispensable to modern technology. They are used in electric motors for vehicles, drones, robots and missiles, as well as powering artificial intelligence servers and smartphones in jet engines, lasers and computer chips. In these metals, heavy rare earth is particularly important for the production of magnets capable of maintaining high temperatures or electric fields.

Daniel Picard, chairman of the Critical Minerals Advisory Committee for the US Trade Representative and Department of Commerce, warned of serious impacts on US industries, if export restrictions remain. “A continuous disruption can damage China’s reputation as a reliable supplier,” Picard said.

China’s monopoly on rare earth is well documented. By 2023, it produced 99 percent of the world’s heavy rare Earth metals and continued to manufacture 90 percent of the rare Earth magnets globally. The remaining production comes from Japan and Germany, both of them depend on the Chinese raw materials.

The mountain pass mine in California owned by MP material is the only US-based source of rare Earth, but cannot meet domestic demand. James Litinsky, CEO of MP Materials, expressed concern over the implications for military contractors. “Drone and robotics are widely considered the future of war,” Litinsky said. “Depending on what we are seeing, important inputs for our future supply chain are closed.”

Export restrictions have not been equally implemented at Chinese ports. Some customs officers allow shipments with minimal scars of heavy rare earth metals if they are in luck for non-American markets. Other exports demand strict testing to ensure compliance of new rules before allowing exports to proceed. Meanwhile, Chinese authorities have prevented domestic companies from engaging with an expansion list of American firms, making international trade more complicated.

China’s dominance in rare earth production lies in its rich deposit near Longon in Jiangxi province. The region hosts the mines that remove the rare earth through the chemical-intensive processes known to cause severe pollution-a practice temporarily stopped but recently resumed.

Refineries near Longonon process these ores before sending magnets in Ganjhou, including JL Mags rare-Earth company, which supplies major electric vehicle manufacturers such as Tesla and Beddi.

The geopolitical implications of this development are important. The visit to Xi Jinping in JL Mag’s factory in 2019 was widely interpreted as a sign that China could take advantage of its control over the rare earth during trade disputes – a strategy that is now working against the background of stressed with Washington after President Trump’s Tariff Hike earlier this month.